A talk with Guy Nelson of Dynamic Attractions before his appearance at November’s IAAPA trade show:

Disney’s Imagineers and Universal’s Creative team usually get all the credit for blockbuster rides like Soarin’ or Harry Potter and the Forbidden Journey, but neither of those attractions would exist without Dynamic Attractions, one of the most acclaimed independent design/build companies in the amusement industry. A decade ago, CEO Guy Nelson leveraged his stake in steel fabricator Empire Industries to acquire Dynamic Structures and create its sibling, Dynamic Attractions; today, his companies are creating some of the most exciting attractions around the world. Nelson recently spoke with me ahead of Dynamic’s anticipated appearance at November’s IAAPA trade show about his “bobbing and weaving” career path, upcoming Orlando rides his company is rumored to be behind, and more, like:

Transitioning from steel fabrication to the attractions business:

At the time when I bought the company, they’d just been awarded a very large contract for Universal’s [most popular ride] in Orlando. That had just been landed before I bought the company. We also had a ski jump we were building for the Olympics in Vancouver, so we had an eclectic mix of backlog when I bought the company in 2007. Then as time progressed I started to like what I was seeing in the attraction ride system business, and started to shift my focus more towards that.

It was definitely not a lifelong dream to get into [attractions]. In fact, when I bought Dynamic Structures, I bought it because it was a competitor in the steel fabrication business. I bought it to take a competitor out of the market. I didn’t buy it because … I was so insightful that I could see what was coming down the pike 10 years down the road. At the time I was frankly uncertain about that side of the business, because I knew nothing about it. Fortunately the management group convinced me that they knew something about it.

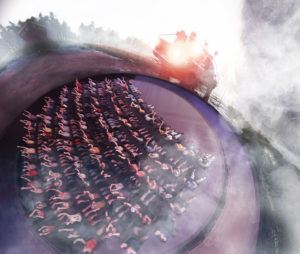

Dynamic’s flying theaters vs. Disney’s Soarin’:

We feel like we’re probably the most knowledgeable people on flying theaters in the world. We built all of Disney’s flying theaters, and we developed our own patented flying theater as well.

Everybody looks at Soarin’ and tries to knock it off. There’s simulator companies that turn their simulators on their end to make it into a flying theater, shaking and rattling and rolling. We like to think that we understand exactly why Soarin’s been so successful on the guest experience side, and we’ve replicated that in a very unique, patented way. And we have not made Disney mad at us for that. They would be mad if I had knocked it off, but we would never do that. We have a couple of competitors that have a pretty good flying theater, but we like to think ours is very good. It’s not just the ride system itself that’s important, it’s the whole package. We have seen too many people not optimize the guest experience by adding terrible movies. Even if we have a spectacular system, if they don’t understand the purpose of the flying theater and how to create the same longevity to the popularity of the ride system, then they are missing the point. That’s how and why we backed into doing it ourselves, because we were tired of other people screwing it up.

Building the successor to Harry Potter and the Forbidden Journey’s ride system:

The contract was awarded in 2016 for a second generation Robocoaster. I don’t think we’ve gone on record yet saying what that is or where that is, but it will be a 2018 opening. Again, we don’t want to make Universal mad at us, so this is a totally different system, but the same sort of approach.

This particular installation has different constraints and parameters: lower throughput, and intermittent dispatch … it’s a different level of complexity on the controls and programming side. But that’s what we do – we have a lot of engineers for a reason. These are the most complicated ride systems in the world, and we’ve got a bunch of them on the go.

Opening Dynamic’s Orlando design center:

We started with 40,000 square feet to demonstrate our work to our customers. Our customers tend to be either coming to Orlando or in Orlando, so it’s a logical place for us to set up operations as opposed to just Vancouver. We’ve gone from 40,000 square feet to 80,000 square feet down there, and it’s grown from a few people to over 25 now. We largely make our designs and build our ride systems in Vancouver, but increasingly we’re doing more and more of our creative work in Orlando.